Business Innovation

In the Driving Seat:

Auto Components in a Time of Change

From providing steel to the car industry, Mitsui raced up the value chain when it took a stake in Gestamp, the world’s leading supplier of highly engineered automotive components.

The automobile business is in a state of flux. Electrification is challenging the century-long dominance of the internal combustion engine, while digital technology is taking self-driving cars from science fiction into everyday reality. Young people, meanwhile, prefer ride-sharing and car-sharing services to outright car ownership. The future leadership of the industry is very much up for grabs and no one knows who will emerge the winner: old-school car manufacturers, brash startups, the giants of big tech or sharing apps.

In the face of change, car manufacturers have taken the strategic decision to focus resources on developing the autonomous driving and anti-collision technologies likely to decide who survives into the next generation. As part of that, they are happy to hand off the responsibility for R&D in more traditional areas, such as the development of sophisticated components, to third parties.

Spain-based Gestamp, a specialist in designing, engineering and manufacturing highly engineered car components, is well positioned to benefit from this outsourcing trend. The company has two great strengths. First, with more than 100 manufacturing facilities in 24 countries, Gestamp has a truly global presence which enables it to provide the same standardized parts to customers wherever they operate. Second, it is a technological leader, particularly in hot stamping (the technology of stamping metal into shapes at temperatures of around 900°C to create lighter and stronger, and thus safer, parts that offer the twin benefits of fuel economy and passenger safety). The company also maintains its lead through a network of more than 1,700 researchers in 13 R&D centers worldwide.

Gestamp’s financial performance testifies to its extraordinary success. In the 25 years since 1997, when the company was founded, sales have risen by over 40 times, propelled by organic growth and strategic M&A.

Deploying Mitsui’s strengths

In June 2013, Mitsui acquired a 30% stake in the North and South American operations of Gestamp and immediately started exploring ways it could raise the value of the business. Then, after nearly three years of collaboration in the Americas, Mitsui deepened its commitment with the acquisition of a 12.5% stake in Gestamp’s parent company in late 2016.

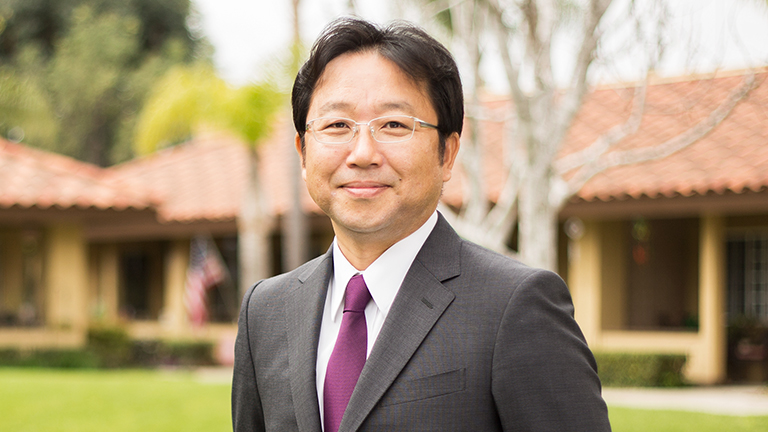

As a Japanese company, the most significant contribution Mitsui can make is to support Gestamp’s efforts at expanding its business with Japanese auto manufacturers. Mitsui has good contacts in the Japanese auto industry and is at home with the Japanese way of doing business. Mitsui staff on secondment to Gestamp rapidly began winning large supply contracts with Japanese car manufacturers globally.

The tie-up with Gestamp also enables Mitsui to update its auto-industry business model. Mitsui, has been supplying steel to the industry since the 1980s. Over time, however, the business model—purchasing sheet steel from Japanese steel makers, cutting it into different sizes and delivering it to component manufacturers on a just-in-time basis—was coming under increasing pressure. Teaming up with Gestamp gives Mitsui greater agency, enabling it to add more value and get closer to the final assembly process.

Mitsui draws on its different strengths to support Gestamp. Take ESG (Environment /Social /Governance) as one example. ESG is one of the most important challenges that Gestamp faces as an energy-intensive, resource-intensive global automotive parts supplier. Through its involvement in a wide range of industries, Mitsui has accumulated a stock of ESG-related knowledge that it can deploy to bolster Gestamp’s ESG strategy and enhance corporate value.

Opening a plant in Japan

In a symbol of Gestamp’s commitment to the Japanese market, the company opened a plant in Matsusaka, Mie Prefecture, in October 2018. Strategically located between Japan’s three major auto clusters in East Japan, Chubu and Northern Kyushu, the plant manufactures Body-in-White components (hoods, doors etc.). Mitsui played a major role in the plant’s gestation, finding a suitable location, arranging the leasing of capital equipment, assisting with hiring and helping with communication with local government. (Mitsui is also involved with plant operation and management.).

It was a particularly opportune moment for Gestamp to set up shop in Japan, with the big Japanese car makers increasingly open to sourcing components from suppliers outside their own keiretsu industrial groupings. The Matsusaka plant currently supplies Japanese car makers with a range of parts and is working on co-development projects with them. In fact, the plant is performing so well that it opened a second hot-stamping line in February 2024.

Moving up a gear

Mitsui’s partnership with Gestamp has been a great success. Mitsui advanced from cutting steel sheet to designing and shaping parts, moved up the added-value ladder and got closer to the car manufacturers and the final assembly process. Gestamp, meanwhile, secured better access to the Japanese auto industry, raised its Japanese market share and acquired a range of new functions. Synergy between the two companies’ complementary strengths no doubt contributed to the 80% rise in Gestamp’s sales since Mitsui first invested in 2013.

And what of the future? No matter how the broad mobility sector evolves in the years to come, vehicles will still be physical objects constructed of steel and other materials. There will still be a premium on strength (for safety) and lightness (for environmental performance). In a changing industry, Gestamp and Mitsui are very much in the driving seat.

Posted in February 2019

Updated in March 2024