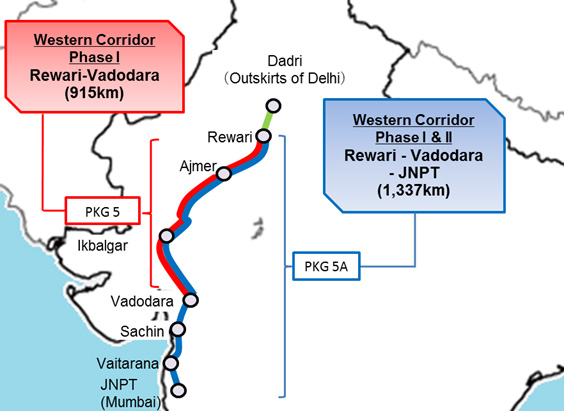

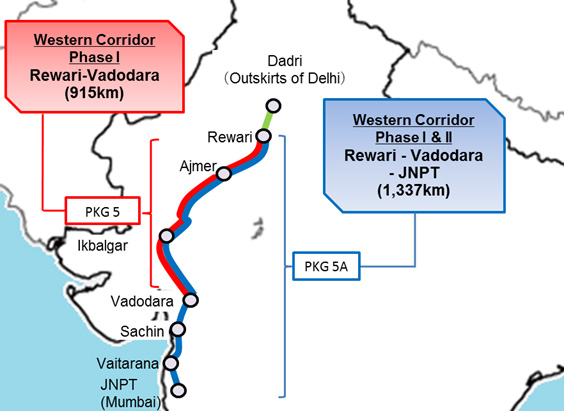

A four-company consortium formed by Mitsui & Co., Ltd. ("Mitsui", Head Office: Tokyo, Japan, President and CEO: Tatsuo Yasunaga), Hitachi, Ltd. ("Hitachi", Head Office: Tokyo, Japan, President and COO: Toshiaki Higashihara), Hitachi India Pvt. Ltd. ("Hitachi India", Head Office: Delhi, India, Managing Director: Kojin Nakakita), a Hitachi subsidiary functioning as the headquarters for Hitachi group companies in India, and a leading company in the rolling stock manufacturing and heavy engineering business in India , has won a contract from the Dedicated Freight Corridor Corporation of India Ltd. (DFCCIL) for the supply and installation of signalling and telecommunications systems along part of a dedicated freight corridor traversing India's biggest industrial cluster between Delhi and Mumbai. The sector covered by the contract ("Package 5"), which is worth a total of approximately ¥28.0 billion (approximately INR 1,800 crore), will cover the 915 km distance between Rewari in the State of Haryana and Vadodara in the State of Gujarat.

In addition, a three-company consortium consisting of Mitsui, Hitachi and Hitachi India has won a contract worth approximately ¥11.0 billion (approximately INR 610 crore) to supply and install an automatic train control system along a 1,337 km section from Rewari in Haryana State to JNPT (Mumbai) in Maharashtra State ("Package 5A").

These two orders are the biggest ever placed in India for Japanese signalling and telecommunications works.

The projects cover the Western Corridor (Delhi-Mumbai), which is part of the Dedicated Freight Corridor ("DFC") project, and will link the four major cities—Delhi, Mumbai, Chennai, and Kolkata—of India's "Golden Quadrilateral". The purpose of the projects is to meet demand for domestic freight transportation resulting from India's rapid economic growth over the past few years. The Indian government has been forming the projects with cooperation from Japan. For example, the Japan International Cooperation Agency (JICA) has been providing assistance for preparatory surveys and verification trials. The Japanese government is also providing yen loans under the Special Terms for Economic Partnership (STEP) on condition that Japanese technology is used.

As consortium leader for Package 5, Hitachi will manufacture key equipment for the signalling system. Mitsui will provide overall coordination with DFCCIL and related agencies in Japan and India. Hitachi India will procure and supply locally made products.

Signalling and telecommunications equipment supplied to DFCCIL under Package 5 will include a train monitoring and diagnostic system that will provide centralized monitoring of each train's position on the track, electronic interlocking equipment to ensure the safe operation of trains by controlling signal lights and points, level crossing warning systems designed to activate automatically when a train is approaching, and a telecommunications system to link all of these systems. Designed to conform to the technical standards of Indian Railways, all this equipment has been used extensively in Japan. Package 5 will contribute to the creation of a safe and modern logistics infrastructure system in India.

As consortium leader for Package 5A, Hitachi will manufacture key equipment for the automatic train control system. Mitsui will provide overall coordination with DFCCIL and related agencies in Japan and India. Hitachi India will procure and supply locally made products and carry out installation work.

Automatic train control system (also called train protection and warning system in India) to be supplied to DFCCIL under Package 5A will be based on the European Train Control System (ETCS) standard. To avoid collisions, rail vehicle brakes are automatically applied based on signals transmitted from the ground device to the trains. The ETCS standard was developed as an inter-city train control system and supports interoperability across national borders in Europe. Installation of the ETCS is mandatory in Europe under an EU Directive, and is also used in other countries outside the EU.

These two projects will result in the creation of train operating systems with the same levels of safety and efficiency as systems in Japan.

A key advantage for Hitachi is its ability to offer one-stop railway solutions covering all aspects from rolling stock systems to signal systems. It was the first Japanese manufacturer to meet the ETCS standard and to acquire TSI*1, which indicates conformance to the ETCS standard, and has developed ETCS-compliant signalling products. In addition to the main-line signalling systems covered by these orders, Hitachi has also supplied signalling systems for urban transportation networks in China and Singapore. It has also been selected to supply signalling equipment, including centralized train monitoring systems and electronic interlocking systems, for use on main rail lines in Vietnam and Myanmar.

In August 2015 Mitsui, Ircon International Limited, a company affiliated with the Indian Ministry of Railways, and Tata Projects Limited, a construction contractor in the Tata Group, jointly won a contract for track-laying and civil engineering work on two continuous sectors totalling 320 km between Vaitarana, in the State of Maharashtra, and Vadodara, in the State of Gujarat. The contracts for Package 5 and Package 5A follow on from this success.

Hitachi India, in collaboration with Rail Systems Company of Hitachi, provides solutions for subways, monorails and other urban transportation systems in India and other south Asian countries, as well as solutions for systems mainly related to rolling stock and signalling for Indian Railways.

Mitsui and Hitachi will continue to work on these projects, which symbolize government-level cooperation between Japan and India. The two companies will also continue to contribute to further economic development of India by helping to meet anticipated growth in the demand for core infrastructure by playing an active role in urban transportation and inter-city high-speed rail projects, and through the introduction of advanced Japanese railway technology.

*1 TSI (Technical Specification for Interoperability): This is a set of technical requirements for train interoperability on inter-city lines. Signalling equipment must conform to European safety standards and the ETCS standard.

Outline of the Project (Package 5)

| Track length |

Rewari-Vadodara: 915 km (PKG5 in diagram below) |

| Contract amount |

Total of approximately ¥28.0 billion |

| Delivery period |

338 weeks (approximately 6.5 years) from start of work |

| Use |

Freight railway |

| Nature of work |

Railway signalling and telecommunications equipment installation |

Outline of the Project (Package 5A)

| Track length |

Rewari-JNPT: 1,337 km (PKG5A in diagram below) |

| Contract amount |

Total of approximately ¥11.0 billion |

| Delivery period |

442 weeks (approximately 8.5 years) from start of work |

| Use |

Freight railway |

| Nature of work |

Railway signalling equipment installation |

Section Covered by Contract

Notice:

This announcement contains forward-looking statements. These forward-looking statements are based on Mitsui's current assumptions, expectations and beliefs in light of the information currently possessed by it and involve known and unknown risks, uncertainties and other factors. Such risks, uncertainties and other factors may cause Mitsui's actual results, financial position or cash flows to be materially different from any future results, financial position or cash flows expressed or implied by these forward-looking statements. These risks, uncertainties and other factors referred to above include, but are not limited to, those contained in Mitsui's latest Annual Securities Report and Semi-annual Securities Report, and Mitsui undertakes no obligation to publicly update or revise any forward-looking statements.

This announcement is published in order to publicly announce specific facts stated above, and does not constitute a solicitation of investments or any similar act inside or outside of Japan, regarding the shares, bonds or other securities issued by us.